Mirrorimg's build thread

- Thread starter mirrorimg

- Start date

mirrorimg

Well-Known Member

I picked up a new-to-me transmission a couple weeks ago, cleaned it up, and started taking it apart. Its a B16 (EM1) non-LSD transmission. I'm ordering a synchrotech rebuild kit to replace all the syncros, hubs, and bearings, but wont be doing anything with the differential. Its cost prohibitive at this time with all the other projects I have going on.

I picked it up from a guy a friend knows for $400. All of the mount bolts are stripped (only noticed that one was stripped when I got it) so it will require some helicoil/timeserts. I may let my machine shop do that work in the event I drop it off to get tumbled.

I was thinking about putting my LS fifth into the B16 transmission, but I will see how I like the B16 fifth for the time being. My highway driving is usually short stints of 30min or less.

On to the pics!

I picked it up from a guy a friend knows for $400. All of the mount bolts are stripped (only noticed that one was stripped when I got it) so it will require some helicoil/timeserts. I may let my machine shop do that work in the event I drop it off to get tumbled.

I was thinking about putting my LS fifth into the B16 transmission, but I will see how I like the B16 fifth for the time being. My highway driving is usually short stints of 30min or less.

On to the pics!

Samurai_Blue

Yolo Whippin'

i suggest getting a new diff for that transmission Jason. B16 differentials are the same as LS diffs, so anything beyond driving normal and occasional spirited driving will kill the diff.

mirrorimg

Well-Known Member

Thanks Dylan, I've heard that while searching for a transmission. Unfortunately, i dont have the scratch for it now. In the future, I will pick up a 1way LSD. I dont plan on doing anything other than daily driving it until I have another vehicle. I also read that the LS is slightly stronger and shares the same bolt pattern, so should anything happen ill scavenge that one!

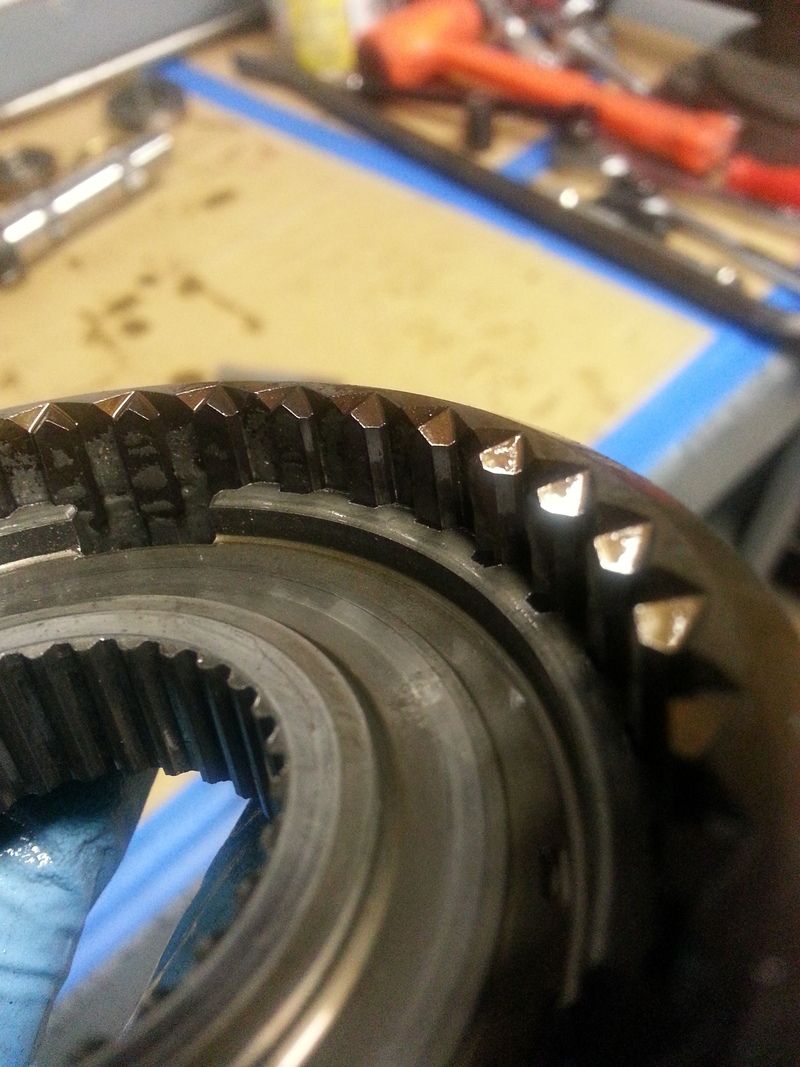

I took the mainshaft apart to see what I was working with. The teeth on the slider sleeves (i think thats what theyre called) are ALL TORN up. I ordered a complete kit so these will also be replaced. Ive got a feeling my third and fifth are like this in my LS trans :???: I always grind third in high rpm shifts.

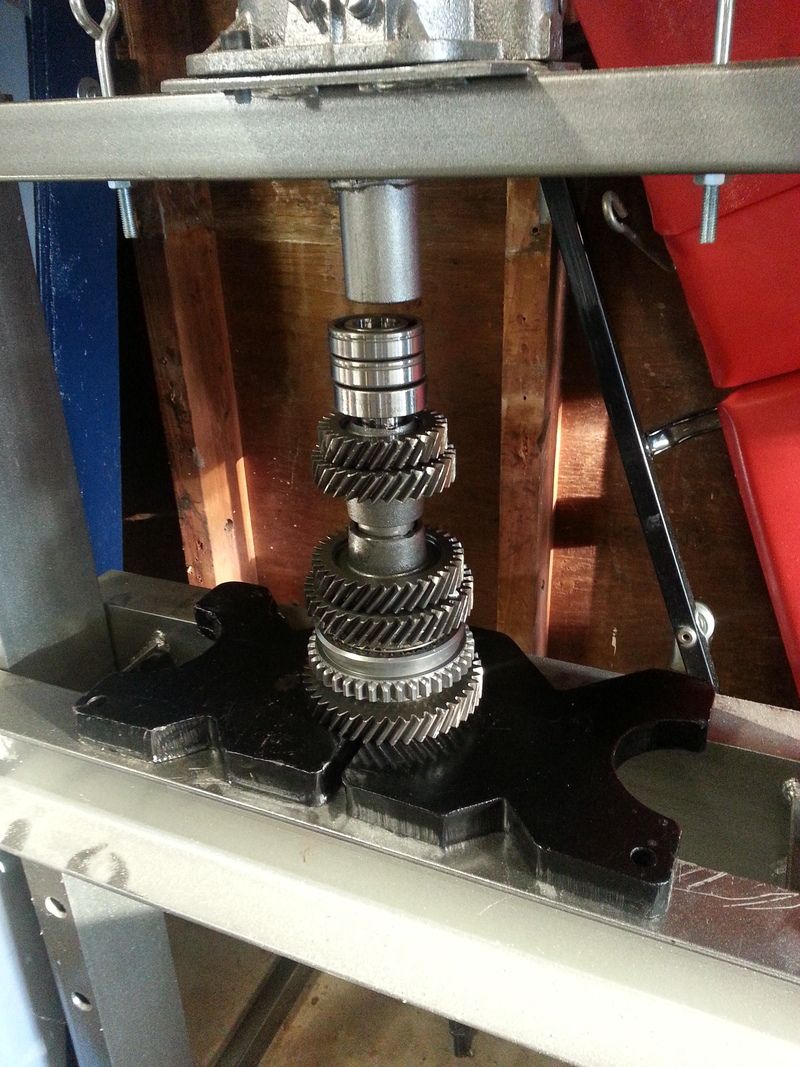

Split up. I put it back together when I was done until the replacement parts arrive.

A couple of the sleeves with bad teeth. This thing must have been really grinding badly.

The one nice side. Must have been fifth.

I took the mainshaft apart to see what I was working with. The teeth on the slider sleeves (i think thats what theyre called) are ALL TORN up. I ordered a complete kit so these will also be replaced. Ive got a feeling my third and fifth are like this in my LS trans :???: I always grind third in high rpm shifts.

Split up. I put it back together when I was done until the replacement parts arrive.

A couple of the sleeves with bad teeth. This thing must have been really grinding badly.

The one nice side. Must have been fifth.

Samurai_Blue

Yolo Whippin'

im in the same boat as you. Im looking for a new transmission lol

mirrorimg

Well-Known Member

I got the rebuild kit on Saturday and noticed it on the porch Monday morning. When I had time in the late afternoon I unboxed it and went to town. It didnt take long but had some trouble pressing the countershaft back together, I didnt have it set up right and had to adjust to press it back together properly. The shafts are all set and now I just need to get the transmission case from the machine shop.

I read some issue people have had with carbon/carbon coated synchros with them sticking if they werent soaked prior to installation. Because I didnt do this, Im going to go back and try to lube them individually without taking it apart, and before installing in the car go through the gears on the bench.

I read some issue people have had with carbon/carbon coated synchros with them sticking if they werent soaked prior to installation. Because I didnt do this, Im going to go back and try to lube them individually without taking it apart, and before installing in the car go through the gears on the bench.

Samurai_Blue

Yolo Whippin'

woot!

Ted's Owner

On to Integra number two!

Looks good!

mirrorimg

Well-Known Member

Time for some more maintenance!

A month or so ago I ordered a set of the Hardrace bushings from TunerSports. When Hardrace shipped them, they put in a set of ITR rear LCA bushings instead of front UCA's, but TunerSports was great in getting that sorted out.

I finished the front side doing the LCA, UCA & Compliance bushings, Lower ball joints, Upper ball joints, and sway bar end links. I also had to replace a inner tie rod bellow and both tie rod end boots. It went pretty smoothly because the front has been taken apart several times for maintenance here and there.

The rear has not been so easy. The rear UCA's, even though the hard race set wont fit in the after market UCAs I have, are a bit frozen on one end so I am working through freeing that up. The passenger side came apart pretty easy except for the nut on the inner most LCA bolt breaking free from its welds. I will need to tack that back in place when everything goes back together.

The driverside LCA has got me in a jam. the bolt that connects to the trailing arm is frozen. The bolt head is starting to strip, so I will soak it in some penetrating oil and give it another shot before welding a bigger nut on the end and cranking it off. It will definitely need a new bolt when it goes back together.

As you can see, the RTA's are in much need of replacement!

A month or so ago I ordered a set of the Hardrace bushings from TunerSports. When Hardrace shipped them, they put in a set of ITR rear LCA bushings instead of front UCA's, but TunerSports was great in getting that sorted out.

I finished the front side doing the LCA, UCA & Compliance bushings, Lower ball joints, Upper ball joints, and sway bar end links. I also had to replace a inner tie rod bellow and both tie rod end boots. It went pretty smoothly because the front has been taken apart several times for maintenance here and there.

The rear has not been so easy. The rear UCA's, even though the hard race set wont fit in the after market UCAs I have, are a bit frozen on one end so I am working through freeing that up. The passenger side came apart pretty easy except for the nut on the inner most LCA bolt breaking free from its welds. I will need to tack that back in place when everything goes back together.

The driverside LCA has got me in a jam. the bolt that connects to the trailing arm is frozen. The bolt head is starting to strip, so I will soak it in some penetrating oil and give it another shot before welding a bigger nut on the end and cranking it off. It will definitely need a new bolt when it goes back together.

As you can see, the RTA's are in much need of replacement!

mirrorimg

Well-Known Member

Well this has been a pretty huge nightmare so far.

I had the nut on the passenger side rear on the end of the innermost portion of the LCA break free from its welds, so I will have to tack it back in place. The driver side toe arm bushing was frozen to the bolt, so I had to cut it our and get a new toe arm. Once that was out, the nut that captures the toe arm bolt fell into the pocket, which means I had to cut a window and set it back where it needed to go.

Everything is back together for the most part so I am making some cribbing blocks to elevate the car with the suspension compressed, not a fan of putting jack stands under the control arms nowadays. I got enough material to lift it off the ground on all 4 corners about 6 inches, so I plan on doubling that in the future (sooner than later to weld that nut) to get 12-14" of lift. I'll take a few pics of that tomorrow.

I had the nut on the passenger side rear on the end of the innermost portion of the LCA break free from its welds, so I will have to tack it back in place. The driver side toe arm bushing was frozen to the bolt, so I had to cut it our and get a new toe arm. Once that was out, the nut that captures the toe arm bolt fell into the pocket, which means I had to cut a window and set it back where it needed to go.

Everything is back together for the most part so I am making some cribbing blocks to elevate the car with the suspension compressed, not a fan of putting jack stands under the control arms nowadays. I got enough material to lift it off the ground on all 4 corners about 6 inches, so I plan on doubling that in the future (sooner than later to weld that nut) to get 12-14" of lift. I'll take a few pics of that tomorrow.

mirrorimg

Well-Known Member

Here's some build pics of the cribbing blocks I made. I need to put end blocks on each one to keep the car from rolling off unexpectedly, which will also prepare it for a second level. Won't be making that yet as this was able to suffice, but more height would be great. I just need some idea of lifting the car high enough to get another level in there though.

Samurai_Blue

Yolo Whippin'

nice work man! i was thinking of getting some of those plinths to do at home alignments. would be super easy to adjust toe.