HooliganSKATE

New Member

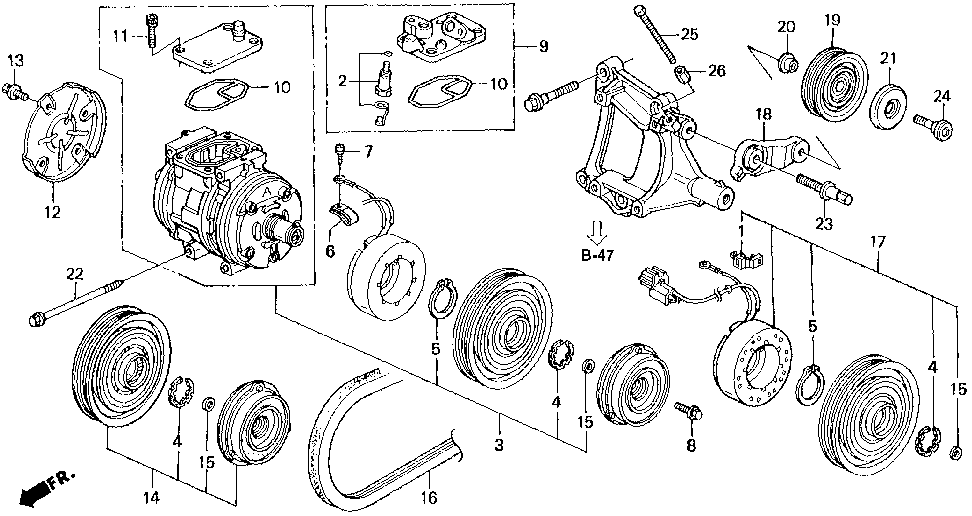

My idler pulley broke off on my way home tonight, the bolt sheared right clean off so its flush with the hole it goes in..

So I know I need to get that bolt out, but how much of my pulley can I re use? is it just a matter of getting that bolt out and replacing it then putting my pulley and arm back on? or do I need a new pulley and arm? I'm not entirely sure of how this all works with this AC belt to be completely honest, as I have never done any work on it. When I get it back on, how do I tension that belt to the correct amount of tension? Just not sure how tight it should be, or how to make the adjustment.

I plan to fix this tomorrow, but if I can't for some reason, I have my ac belt just on the two pulleys loosely right now, will it be alright to drive the car like this so I can get to and from work Thursday?

Thanks for the help guys!

So I know I need to get that bolt out, but how much of my pulley can I re use? is it just a matter of getting that bolt out and replacing it then putting my pulley and arm back on? or do I need a new pulley and arm? I'm not entirely sure of how this all works with this AC belt to be completely honest, as I have never done any work on it. When I get it back on, how do I tension that belt to the correct amount of tension? Just not sure how tight it should be, or how to make the adjustment.

I plan to fix this tomorrow, but if I can't for some reason, I have my ac belt just on the two pulleys loosely right now, will it be alright to drive the car like this so I can get to and from work Thursday?

Thanks for the help guys!

Last edited: