Anyways I had got a new set of CP rings, Upgraded CP wrist pins, With new CP wrist pins locks from real street performance, Should be in tomorrow morning. I just plastigauged my main bearings tonight. The first reading wasn't the best so I redid the plastigauge. (Plastigauge reads .0015, .0020, .0010, etc. So I use 2 different ones and put the numbers as close to what it looks like accordingly. Also I measured the plastigauge on the caps and on the crank. They're probably all the same, But I just did as before and wrote down what It looked like. These were all done with ACL Race standard GSR bearings. I have no idea how to convert these to figure out what OEM bearings would be the right fit. I am wanting .0015" on all but main bearing 3 which I want .0017". I'm about to do some research and maybe figure out how to convert to oem bearing colors/sizes but if anyone already knows and can help out let me know!

Also I know there's codes on the block/crank (letters/numbers?) To see what bearing colors should go there. (I'm not sure if It's the stock crank to that block though) but maybe it could help, Maybe not?

ACL Race bearings are all 2.007mm / .0790"

These are the clearences with acl's on my motor

#1 .0015"

#2 .0011"

#3 .0011"

#4 .0013"

#5 .0013"

Which bearing would I need in order to get these

#1 .0015"

#2 .0015"

#3 .0017"

#4 .0015"

#5 .0015"

Here's OEM bearing chart

Main Bearing thickness by color

Blue 2.013-2.010 mm 0.0793”- 0.0791”

Black 2.010-2.007 mm 0.0791”- 0.0790”

Brown 2.007-2.004 mm 0.0790”- 0.0789”

Green 2.004-2.001 mm 0.0789”- 0.0788”

Yellow 2.001-1.998 mm 0.0788”- 0.0787”

Pink 1.998-1.995 mm 0.0787”- 0.0785”

Red 1.995-1.992 mm 0.0785”- 0.0783”

What I can come up with is

#1 Brown

#2 Pink

#3 Pink or Red?

#4 Green

#5 Green

Anyone want to chime in?

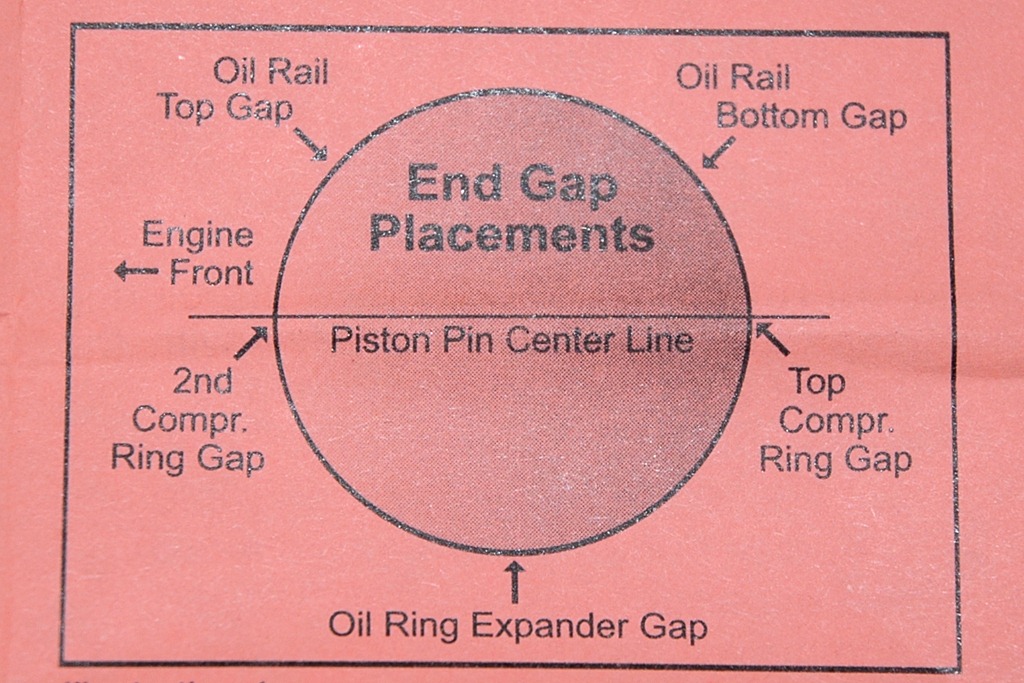

Also I can't decide whether to stay pump 93 or go e85! If I got e85 I want to run smaller piston ring gaps because the e85 will run alot cooler, I'm looking at running .022" upper .024" lower .015" oil ring on 93 and about .019" upper .021" lower and .015" oil ring on e85. Can't decide though

I'll be able to make alot more power with e85 and run cooler, And alot less chance of detonation.) E85 sounds like a win win, Especially since I have a e85 station right around the corner. Except i'll need a way bigger fuel system if I want to reach my goal of 600whp with e85 which will be alot of $