Muckman’s High Compression Super Build

HooliganSKATE

New Member

Holt shit muckman, your car is faking beautiful!! I wish my car was as red as yours, how long have you owned this car? Subscribed for sure

95B18BTurbo

New Member

Yep, your car sir is pure sex all the way around!

Muckman

Not a M0derator

I bought it new off show room floor in 2000. Been turbo'd since 2004. Only has 76k on the odo.how long have you owned this car?

JustinMcGee1

I like Hondas

So it's not a daily I assume?

this post was made in china using Taptalk2

this post was made in china using Taptalk2

JustinMcGee1

I like Hondas

You should take it to the 1/4 mile and post the times!

this post was made in china using Taptalk2

this post was made in china using Taptalk2

JustinMcGee1

I like Hondas

that's one fast integra lol

this post was made in china using Taptalk2

this post was made in china using Taptalk2

cody1018

Member

That's what she said.... :nod:

That's amazing muckman to see numbers like that off of e85. Do you happen to have a dyno video?

Sent from Wonka's chocolate factory using tapatalk 2

DaddyBuiltRacing

Resident Asshole

Trap speed of 130 will put you in the 10s.. I'm in for this build as well!

Muckman

Not a M0derator

Check out 3rd post. Updated with videos from 2012 dyno day.Do you happen to have a dyno video?

Muckman

Not a M0derator

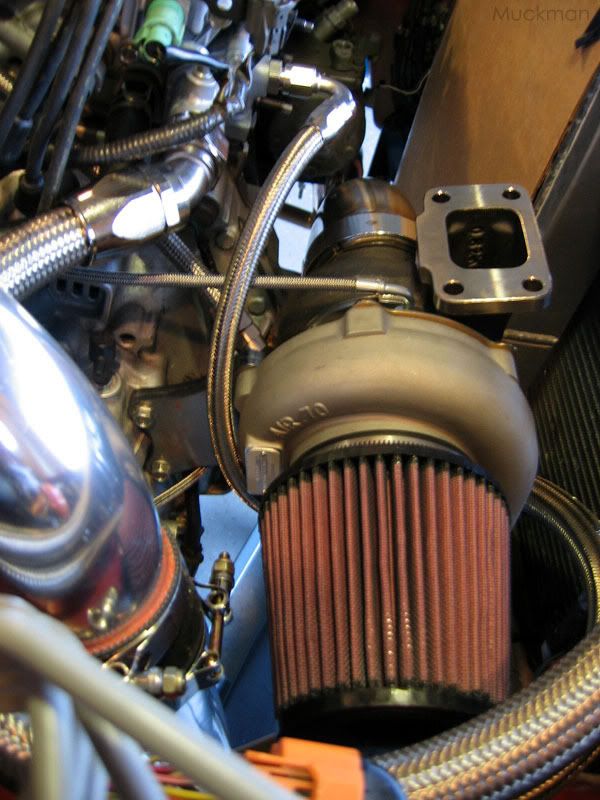

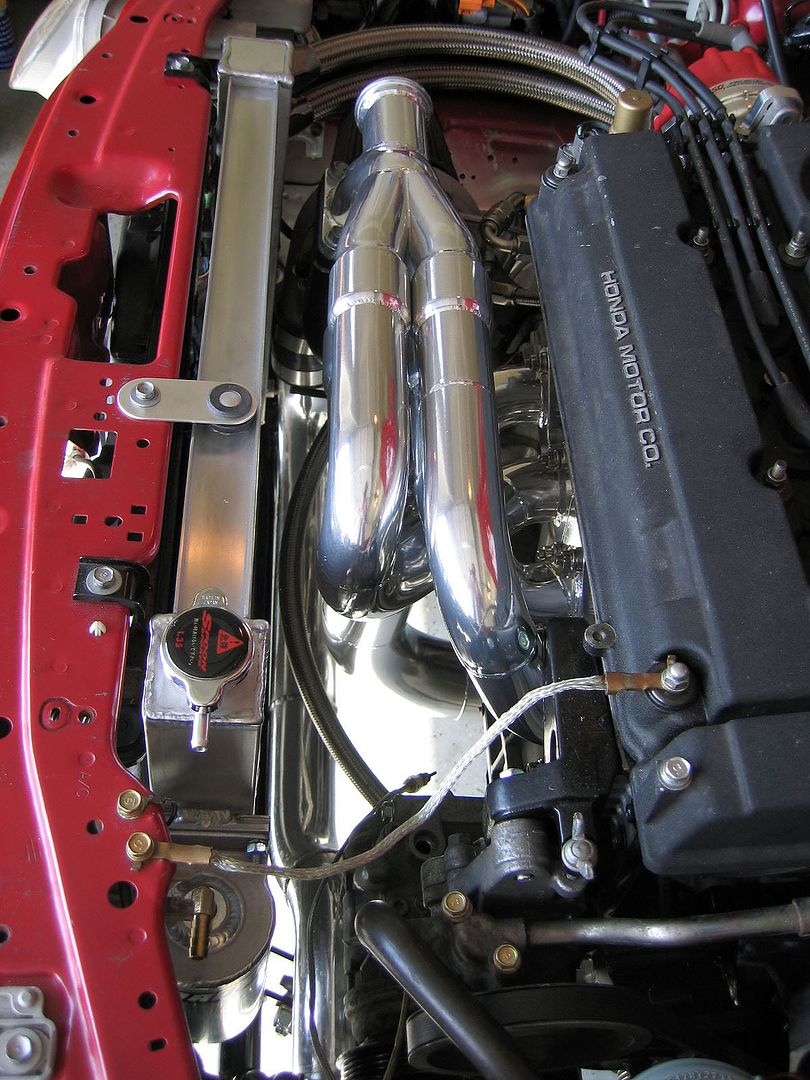

These pictures are from 2008 when I started work on my current turbo setup with the new turbo and new manifold. I thought you guys might like the eye candy.

New GT3076R-13 on right. Custom S cover with anti-surge, GT .82 AR turbine. Old Precision SC3134E on left. Both similar in size.

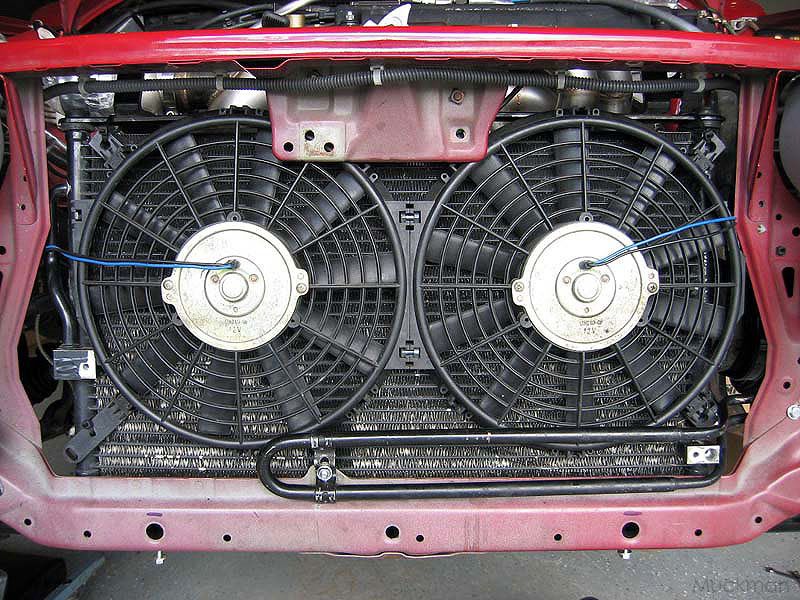

Two 12” pusher fans mounted in 22” of horizontal space. I had to trim the shrouds to make them fit. I drilled out the PS cooler beam and mounted the PS cooler loop on the bottom.

Mounting the Precision 750 intercooler to the crash beam.

I really didn’t want to cut out the black bumper grill. It was a very tight fit (overall theme of this build) but I made it fit by angling the intercooler down slightly.

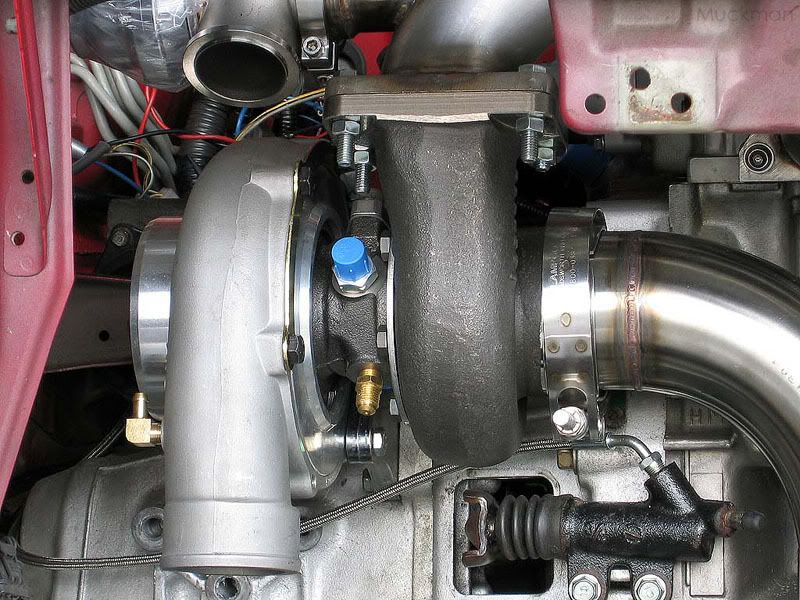

Test fitting the turbo to manifold. Had to remove the rubber boot around the clutch fork and use a custom hose to avoid contact with turbine housing.

I love this underneath shot of the manifold. This is before I had it ceramic coated. Was still contemplating how to route the wastegate dump tube. Originally wanted to route it foward but new water hoses would occupy that space.

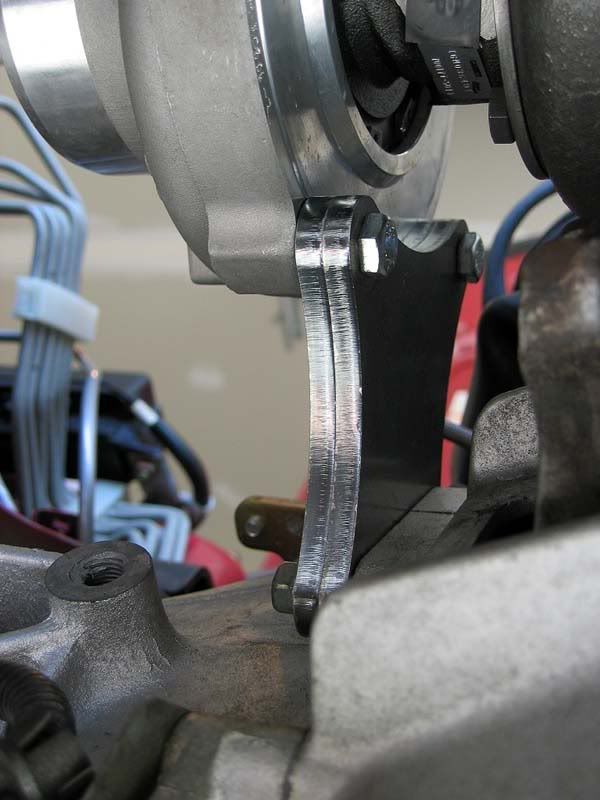

Here are a couple pictures of the turbo brace I designed. It uses the stock clutch line bracket mount on the trans to support the weight of the turbo. The manifold is made from thin walled 16 gauge 304 stainless so I needed to relieve the stress of the turbo. I drew up a mechanical drawing and had a friend cut it out of two ¼” pieces of stainless with a CNC laser cutter (pew pew).

Welded -16 An bungs to the water necks. Welding cast aluminum sucks. Needed alternative water hoses to route around turbo. Im using the empty port (the bleeder port on older integras) on the front water neck as a water source for the turbo (not shown).

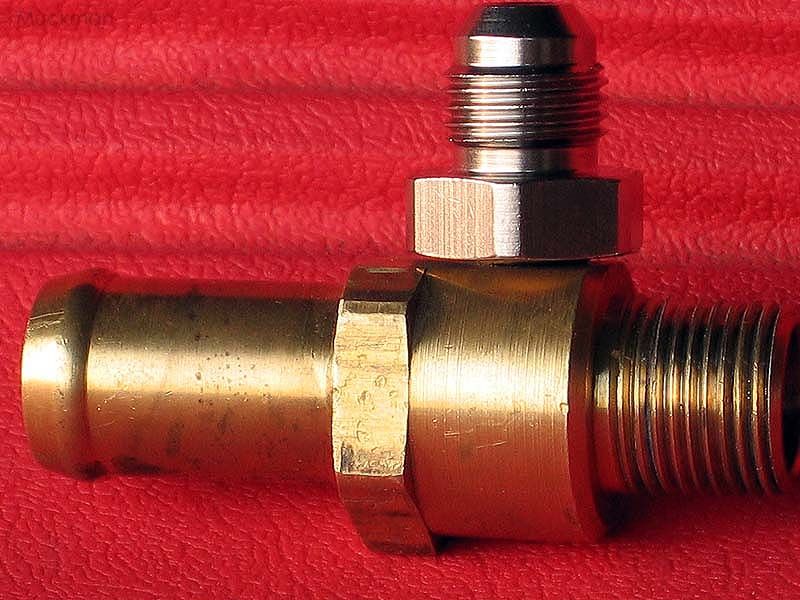

Drilled out this brass water fitting that is used on the Edelbrock VictorX intake manifold so I could T a water return hose of it for the turbo. -6AN

Had to shave and counter sink the upper power steering bracket because runner #1 would hit the bolt. I didn’t want to shave the bolt, that would be hacky. Lots of clearance issues on this setup!

Needed a place away from the heat but close to the distributor to mount the MSD blaster SCI coil. Used threaded nutserts and washers to make the rubber stand offs level. This is behind the ABS system on the fender wall.

Routing the plumbing for the turbo. Im using -6 braided hose for the water lines and -4 for oil feed with a restrictor. -10 for oil drain. I bought a custom sized K&N filter to fit the small space. But it ended up being a restriction on the dyno so I dont run it anymore.

Here is everything finished. That was my first custom radiator. I didn’t like it so I had another one made. Finally figured out how to route the wastegate dump tube.

Another great picture of the manifold. Pre ceramic.

Custom radiator 2.0 – dual pass, -16AN ports, full width, dual core with the over flow tank mounted on the side. Its looks much better than the first version plus its bigger.

Test fitting the hood would close without contacting the tial blow off valve. I made all the charge piping. 2.5” hot side, 2.75” cold side.

Here are a couple pics with the new radiator installed and the manifold ceramic coated. Look at how much nicer that new radiator is. The overflow can is tucked away too. Even the mounting tab came out nice.

New GT3076R-13 on right. Custom S cover with anti-surge, GT .82 AR turbine. Old Precision SC3134E on left. Both similar in size.

Two 12” pusher fans mounted in 22” of horizontal space. I had to trim the shrouds to make them fit. I drilled out the PS cooler beam and mounted the PS cooler loop on the bottom.

Mounting the Precision 750 intercooler to the crash beam.

I really didn’t want to cut out the black bumper grill. It was a very tight fit (overall theme of this build) but I made it fit by angling the intercooler down slightly.

Test fitting the turbo to manifold. Had to remove the rubber boot around the clutch fork and use a custom hose to avoid contact with turbine housing.

I love this underneath shot of the manifold. This is before I had it ceramic coated. Was still contemplating how to route the wastegate dump tube. Originally wanted to route it foward but new water hoses would occupy that space.

Here are a couple pictures of the turbo brace I designed. It uses the stock clutch line bracket mount on the trans to support the weight of the turbo. The manifold is made from thin walled 16 gauge 304 stainless so I needed to relieve the stress of the turbo. I drew up a mechanical drawing and had a friend cut it out of two ¼” pieces of stainless with a CNC laser cutter (pew pew).

Welded -16 An bungs to the water necks. Welding cast aluminum sucks. Needed alternative water hoses to route around turbo. Im using the empty port (the bleeder port on older integras) on the front water neck as a water source for the turbo (not shown).

Drilled out this brass water fitting that is used on the Edelbrock VictorX intake manifold so I could T a water return hose of it for the turbo. -6AN

Had to shave and counter sink the upper power steering bracket because runner #1 would hit the bolt. I didn’t want to shave the bolt, that would be hacky. Lots of clearance issues on this setup!

Needed a place away from the heat but close to the distributor to mount the MSD blaster SCI coil. Used threaded nutserts and washers to make the rubber stand offs level. This is behind the ABS system on the fender wall.

Routing the plumbing for the turbo. Im using -6 braided hose for the water lines and -4 for oil feed with a restrictor. -10 for oil drain. I bought a custom sized K&N filter to fit the small space. But it ended up being a restriction on the dyno so I dont run it anymore.

Here is everything finished. That was my first custom radiator. I didn’t like it so I had another one made. Finally figured out how to route the wastegate dump tube.

Another great picture of the manifold. Pre ceramic.

Custom radiator 2.0 – dual pass, -16AN ports, full width, dual core with the over flow tank mounted on the side. Its looks much better than the first version plus its bigger.

Test fitting the hood would close without contacting the tial blow off valve. I made all the charge piping. 2.5” hot side, 2.75” cold side.

Here are a couple pics with the new radiator installed and the manifold ceramic coated. Look at how much nicer that new radiator is. The overflow can is tucked away too. Even the mounting tab came out nice.

Last edited:

95B18BTurbo

New Member

Damn that is clean as hell!