jbrown97ls

Active Member

Favorite build on Club Integra hands down.

And it's not even a Honda, lol. Definitely one of my favorites as well though:

Favorite build on Club Integra hands down.

Junk by Austin Rajki, on Flickr

Junk by Austin Rajki, on Flickr Junk by Austin Rajki, on Flickr

Junk by Austin Rajki, on Flickr Junk by Austin Rajki, on Flickr

Junk by Austin Rajki, on Flickr New Junk by Austin Rajki, on Flickr

New Junk by Austin Rajki, on Flickr New Junk by Austin Rajki, on Flickr

New Junk by Austin Rajki, on Flickr New Junk by Austin Rajki, on Flickr

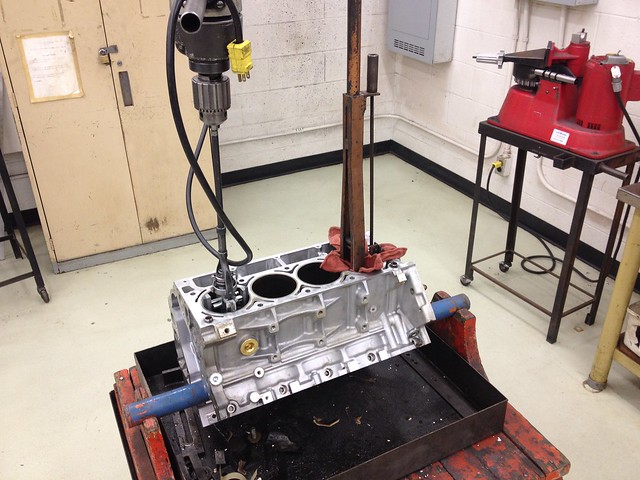

New Junk by Austin Rajki, on Flickr Cam Journals Align Honed by Austin Rajki, on Flickr

Cam Journals Align Honed by Austin Rajki, on Flickr Honing by Austin Rajki, on Flickr

Honing by Austin Rajki, on Flickr by Austin Rajki, on Flickr

by Austin Rajki, on Flickr by Austin Rajki, on Flickr

by Austin Rajki, on Flickr by Austin Rajki, on Flickr

by Austin Rajki, on Flickr by Austin Rajki, on Flickr

by Austin Rajki, on Flickr Clean by Austin Rajki, on Flickr

Clean by Austin Rajki, on FlickrThanks man! I hope so!Hope everything is smooth sailing from here on out!

Cam Bearings Installed by Austin Rajki, on Flickr

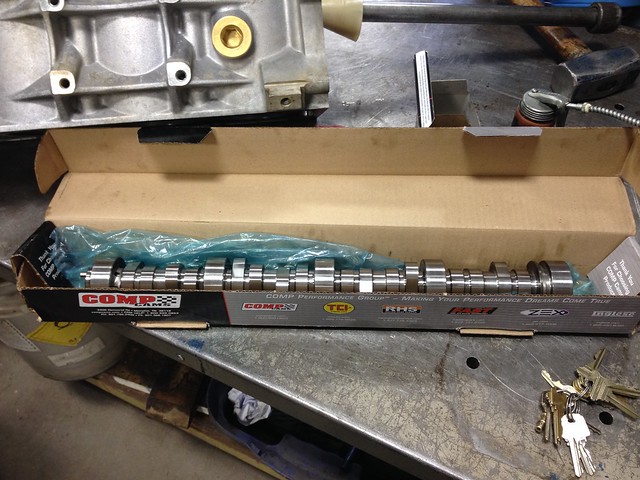

Cam Bearings Installed by Austin Rajki, on Flickr Comp Cams Billet Cam by Austin Rajki, on Flickr

Comp Cams Billet Cam by Austin Rajki, on Flickr Cam Fits and Spins! by Austin Rajki, on Flickr

Cam Fits and Spins! by Austin Rajki, on Flickr Final Assembly by Austin Rajki, on Flickr

Final Assembly by Austin Rajki, on Flickr Final Assembly by Austin Rajki, on Flickr

Final Assembly by Austin Rajki, on Flickr ARP Assembly Lube by Austin Rajki, on Flickr

ARP Assembly Lube by Austin Rajki, on Flickr Sealant on the Side Cap Bolts by Austin Rajki, on Flickr

Sealant on the Side Cap Bolts by Austin Rajki, on Flickr Lubing up the Cam by Austin Rajki, on Flickr

Lubing up the Cam by Austin Rajki, on Flickr Clean Retainer Face by Austin Rajki, on Flickr

Clean Retainer Face by Austin Rajki, on Flickr New Cam Retainer Installed by Austin Rajki, on Flickr

New Cam Retainer Installed by Austin Rajki, on Flickr Crank and Cam In by Austin Rajki, on Flickr

Crank and Cam In by Austin Rajki, on Flickr Pulling Timing Gear/ Oil Pump Drive by Austin Rajki, on Flickr

Pulling Timing Gear/ Oil Pump Drive by Austin Rajki, on Flickr New Gear Installed by Austin Rajki, on Flickr

New Gear Installed by Austin Rajki, on Flickr Ghetto Cam Retainer by Austin Rajki, on Flickr

Ghetto Cam Retainer by Austin Rajki, on Flickr Goodbye 1.6 by Austin Rajki, on Flickr

Goodbye 1.6 by Austin Rajki, on Flickr Goodbye 1.6 by Austin Rajki, on Flickr

Goodbye 1.6 by Austin Rajki, on Flickr Goodbye 1.6 by Austin Rajki, on Flickr

Goodbye 1.6 by Austin Rajki, on FlickrYou betcha! I bought the engine just outside of Detroit, loaded it into the back of the Integra and brought it directly to school. I only brought the parts in the house when they weren't home to take pictures of them then brought them to school.You kept an expensive ass ls1 secret from your parents all this time? :lol:

You betcha! I bought the engine just outside of Detroit, loaded it into the back of the Integra and brought it directly to school

Cutting Valve Seats by Austin Rajki, on Flickr

Cutting Valve Seats by Austin Rajki, on Flickr Washing after Cutting Seats by Austin Rajki, on Flickr

Washing after Cutting Seats by Austin Rajki, on Flickr Valve Lapping by Austin Rajki, on Flickr

Valve Lapping by Austin Rajki, on Flickr Valve Lapping Cream by Austin Rajki, on Flickr

Valve Lapping Cream by Austin Rajki, on Flickr Seats Marked by Austin Rajki, on Flickr

Seats Marked by Austin Rajki, on Flickr Lapping by Austin Rajki, on Flickr

Lapping by Austin Rajki, on Flickr Perfect by Austin Rajki, on Flickr

Perfect by Austin Rajki, on Flickr Perfect by Austin Rajki, on Flickr

Perfect by Austin Rajki, on Flickr Glistening in the Sun by Austin Rajki, on Flickr

Glistening in the Sun by Austin Rajki, on Flickr Ready for Assembly by Austin Rajki, on Flickr

Ready for Assembly by Austin Rajki, on Flickr