The Chronicles of "Harmony" - dopematic's Integra Update Thread

dopematic

New Member

Update I guess..

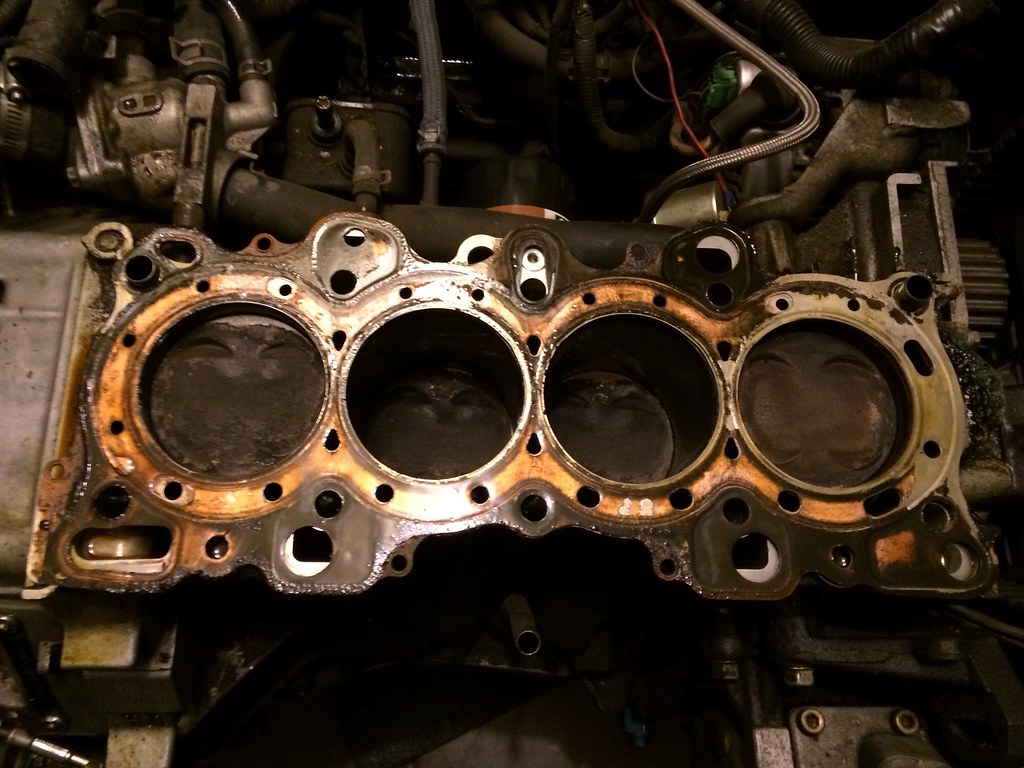

Was suppose to go thunderhill or buttonwillow dec. 21st but an heating issue arised that did not make any sense in which I can source the problem. Turned out to be a blown headgasket.. Ordered parts.. waiting for them to come in and will replace the headgasket first chance I get.

Was suppose to go thunderhill or buttonwillow dec. 21st but an heating issue arised that did not make any sense in which I can source the problem. Turned out to be a blown headgasket.. Ordered parts.. waiting for them to come in and will replace the headgasket first chance I get.

Samurai_Blue

Yolo Whippin'

dopematic

New Member

[YOUTUBE="session 1"]qOYNvc9g4ZA[/YOUTUBE]

[YOUTUBE="session 2"]4gcDBkb8lVA[/YOUTUBE]

So I finally got the chance to load up the videos of my track day in August. Videography is a lot more difficult to upload and whatnot because my netbook is too slow haha

Yes Dylan, you've definitely made a track junkie!!

[YOUTUBE="session 2"]4gcDBkb8lVA[/YOUTUBE]

So I finally got the chance to load up the videos of my track day in August. Videography is a lot more difficult to upload and whatnot because my netbook is too slow haha

Yes Dylan, you've definitely made a track junkie!!

Last edited:

dopematic

New Member

So two months ago, I found that my headgasket blew. I ordered parts to replace it.

-oem head gasket

-timing belt

-tensioner

-tensioner spring

-tensioner bolt

-camshaft gasket

So what many of you don't know is that my block's headstud threads were previously stripped before and repaired with helicoils. It turns out, the helicoils have just failed on me and did not allow me to torque the head back down. I ordered a timesert bigsert oversized kit to repair the threads after a helicoil failure.

Fairly simple procedure if you're familiar with drilling and tapping a new hole for new threads. The kit is basically fool proof and has a plate fixure that allows you to drill directly perpendicular to the block so that the new hole and tapped threads will be as straight as possible. So I spent hours drilling, tapping, and inserting the new stainless steel insert threads into the newly tapped threads. It took foever cause my drill was too weak and the special stepped drill bit that the timesert kit came with was getting really dull even with using wd40 and 10w30 oil for lubrication.

So I got all the new inserts installed. Installed my arp head studs. Ready to torque down the head in sequential order in increments of 20lbs. I got up to 40lbs starting inside out the sequence. Moved up to 60lbs and the newly installed insert which was suppose to stay in place with the newly tapped threads STRIPPED on me.. -_- ... FML. The oversized inserts have a metal pin at the bottom of the insert which gets pushed outward during installation with the special driver tool that the kit came with. In addition, all inserts had loctite RED on them and all inserts were left to sit more than 24 hours before I tried to torque the head down.

Only possibility that I can think of is that the aluminum block itself is getting weak and brittle that the newly tapped threads cannot hold up anymore since it didnt hold up pass 40lbs.

So.. helicoils can be removed manually but can be a b**** to remove. Regular timesert inserts can be removed with a screw extractor according to the timesert website. BIGSERT oversized inserts on the other hand cannot be removed manually but must be machined out. So Ive decided to part ways with my current block and am in search of a new short block.

-oem head gasket

-timing belt

-tensioner

-tensioner spring

-tensioner bolt

-camshaft gasket

So what many of you don't know is that my block's headstud threads were previously stripped before and repaired with helicoils. It turns out, the helicoils have just failed on me and did not allow me to torque the head back down. I ordered a timesert bigsert oversized kit to repair the threads after a helicoil failure.

Fairly simple procedure if you're familiar with drilling and tapping a new hole for new threads. The kit is basically fool proof and has a plate fixure that allows you to drill directly perpendicular to the block so that the new hole and tapped threads will be as straight as possible. So I spent hours drilling, tapping, and inserting the new stainless steel insert threads into the newly tapped threads. It took foever cause my drill was too weak and the special stepped drill bit that the timesert kit came with was getting really dull even with using wd40 and 10w30 oil for lubrication.

So I got all the new inserts installed. Installed my arp head studs. Ready to torque down the head in sequential order in increments of 20lbs. I got up to 40lbs starting inside out the sequence. Moved up to 60lbs and the newly installed insert which was suppose to stay in place with the newly tapped threads STRIPPED on me.. -_- ... FML. The oversized inserts have a metal pin at the bottom of the insert which gets pushed outward during installation with the special driver tool that the kit came with. In addition, all inserts had loctite RED on them and all inserts were left to sit more than 24 hours before I tried to torque the head down.

Only possibility that I can think of is that the aluminum block itself is getting weak and brittle that the newly tapped threads cannot hold up anymore since it didnt hold up pass 40lbs.

So.. helicoils can be removed manually but can be a b**** to remove. Regular timesert inserts can be removed with a screw extractor according to the timesert website. BIGSERT oversized inserts on the other hand cannot be removed manually but must be machined out. So Ive decided to part ways with my current block and am in search of a new short block.

Last edited:

Nick_C78

New Member

That sucks man. I helicoiled my last block too, because of the same reason. I was able to get mine to 70lbs and then when I was finished torqueing and as I stepped back I heard a loud SNAP. Scared the hell out of me. What happened was the OEM threads got ripped out of the block. Helicoil worked though, but that block is garbage now because of over bore. That being said, I feel your pain. I will keep a look out for a block.

JustinMcGee1

I like Hondas

Sorry to hear that, good luck on finding another block man!

Samurai_Blue

Yolo Whippin'

Dillon has a new block and were ready to go hit the track :thumbs up

Samurai_Blue

Yolo Whippin'

is it bad i had to look here to find your user name?

dopematic

New Member

Yes indeed, it is very depressing. It hits me hard at the moment but I've come to get over it faster nowadays than the years past haha. Helicoils did work as well. It lasted 3 years in my block with two track days, multiple drag passes, and over 25k miles. But apparantly the aluminum block just gave out...That sucks man. I helicoiled my last block too, because of the same reason. I was able to get mine to 70lbs and then when I was finished torqueing and as I stepped back I heard a loud SNAP. Scared the hell out of me. What happened was the OEM threads got ripped out of the block. Helicoil worked though, but that block is garbage now because of over bore. That being said, I feel your pain. I will keep a look out for a block.

Thanks bro.Sorry to hear that, good luck on finding another block man!

Dylan is correct. I just picked up LS long block out of a 95 integra automatic. 150k miles. Came with intake manifold and all sensors on intake manifold. That being said, I don't know how I'm going to find time to clean it up and do the swap with work, school, and trying to find volunteer work but in time, I'll eventually find time slowly but surely.Dillon has a new block and were ready to go hit the track :thumbs up

Yes, asswipe. Lol =Pis it bad i had to look here to find your user name?

Samurai_Blue

Yolo Whippin'

oh i have a product for you to try to use to clean up the car.

dopematic

New Member

So I guess I should update this.. about a month and a half? I cant remember exactly long ago I finished my swap and got my car back up and running.

I bought a used longblock off of craigslist for 300, came with complete head which I didnt use. Came out of a 95 Automatic Integra LS, still had the flexplate on it when I picked it up. Also came with a obd1 alternator which I will get tested and probably sell later.

I used the same setup I had before which is just a stock internaled LSVTEC. I just swapped everything over including the Head, Oil pump, Water pump, External Vtec feed line.

Oil pump and water pump only had like 20k miles on them at most, which is the reason why I opted to reuse them.

- Head resurfaced.

- New headgasket

- new gaskets: water pump, oil pump, valve cover, dizzy, oil pan.

- picked up Hondata Intake manifold gasket

Started up with no problems. Motor pulls. Vtec works. No leaks. No CELs. Not overheating.

After about a week of driving, I notice some black specs on my rear bumper. It looks like it is consuming a tad bit of oil -_-.

From inspecting the LS head, there is some slight sludge residue and appears like oil was definitely not changed regularly.

I felt pretty comfortable buying a LS automatic motor because well it's an automatic for the most part wouldn't be abused AS MUCH as a manual. But I guess it wasn't too well maintained either.

I will do a compression test and leakdown test whenever I get to it and have time to confirm whether it be the rings or my valve seals which I have not changed ever.

Here are some pics.

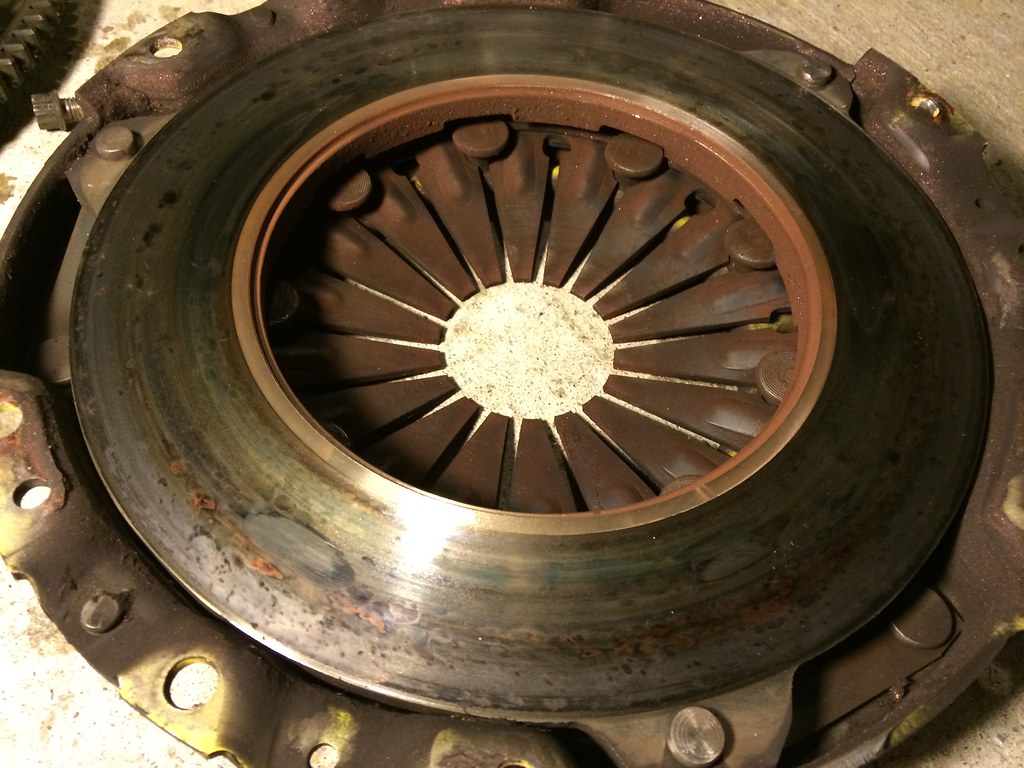

Clutch and pressure plate looks worn down but I decided to reuse it anyways. It had some burn hot spots on the pressure plate. Still grabs good enough for me.

Besides the consumption of oil. With the downtime I had on my car. I am still estatic to have my car back up and running. In addition, I also passed smog and got my tags as well. She still is my daily driver and it feels great to have her back up and running. I was borrowing my brother's stock ek civic hatch and it suck balls. Lol.

So I have decided later on down the road after I get a daily driver. I will build a new motor. Just havent decided on which route I want to go yet. Decisions, Decisions.

Also, I am aiming for July for my retun to the track at Thunderhill :thumbs up

I bought a used longblock off of craigslist for 300, came with complete head which I didnt use. Came out of a 95 Automatic Integra LS, still had the flexplate on it when I picked it up. Also came with a obd1 alternator which I will get tested and probably sell later.

I used the same setup I had before which is just a stock internaled LSVTEC. I just swapped everything over including the Head, Oil pump, Water pump, External Vtec feed line.

Oil pump and water pump only had like 20k miles on them at most, which is the reason why I opted to reuse them.

- Head resurfaced.

- New headgasket

- new gaskets: water pump, oil pump, valve cover, dizzy, oil pan.

- picked up Hondata Intake manifold gasket

Started up with no problems. Motor pulls. Vtec works. No leaks. No CELs. Not overheating.

After about a week of driving, I notice some black specs on my rear bumper. It looks like it is consuming a tad bit of oil -_-.

From inspecting the LS head, there is some slight sludge residue and appears like oil was definitely not changed regularly.

I felt pretty comfortable buying a LS automatic motor because well it's an automatic for the most part wouldn't be abused AS MUCH as a manual. But I guess it wasn't too well maintained either.

I will do a compression test and leakdown test whenever I get to it and have time to confirm whether it be the rings or my valve seals which I have not changed ever.

Here are some pics.

Clutch and pressure plate looks worn down but I decided to reuse it anyways. It had some burn hot spots on the pressure plate. Still grabs good enough for me.

Besides the consumption of oil. With the downtime I had on my car. I am still estatic to have my car back up and running. In addition, I also passed smog and got my tags as well. She still is my daily driver and it feels great to have her back up and running. I was borrowing my brother's stock ek civic hatch and it suck balls. Lol.

So I have decided later on down the road after I get a daily driver. I will build a new motor. Just havent decided on which route I want to go yet. Decisions, Decisions.

Also, I am aiming for July for my retun to the track at Thunderhill :thumbs up